Table of Contents

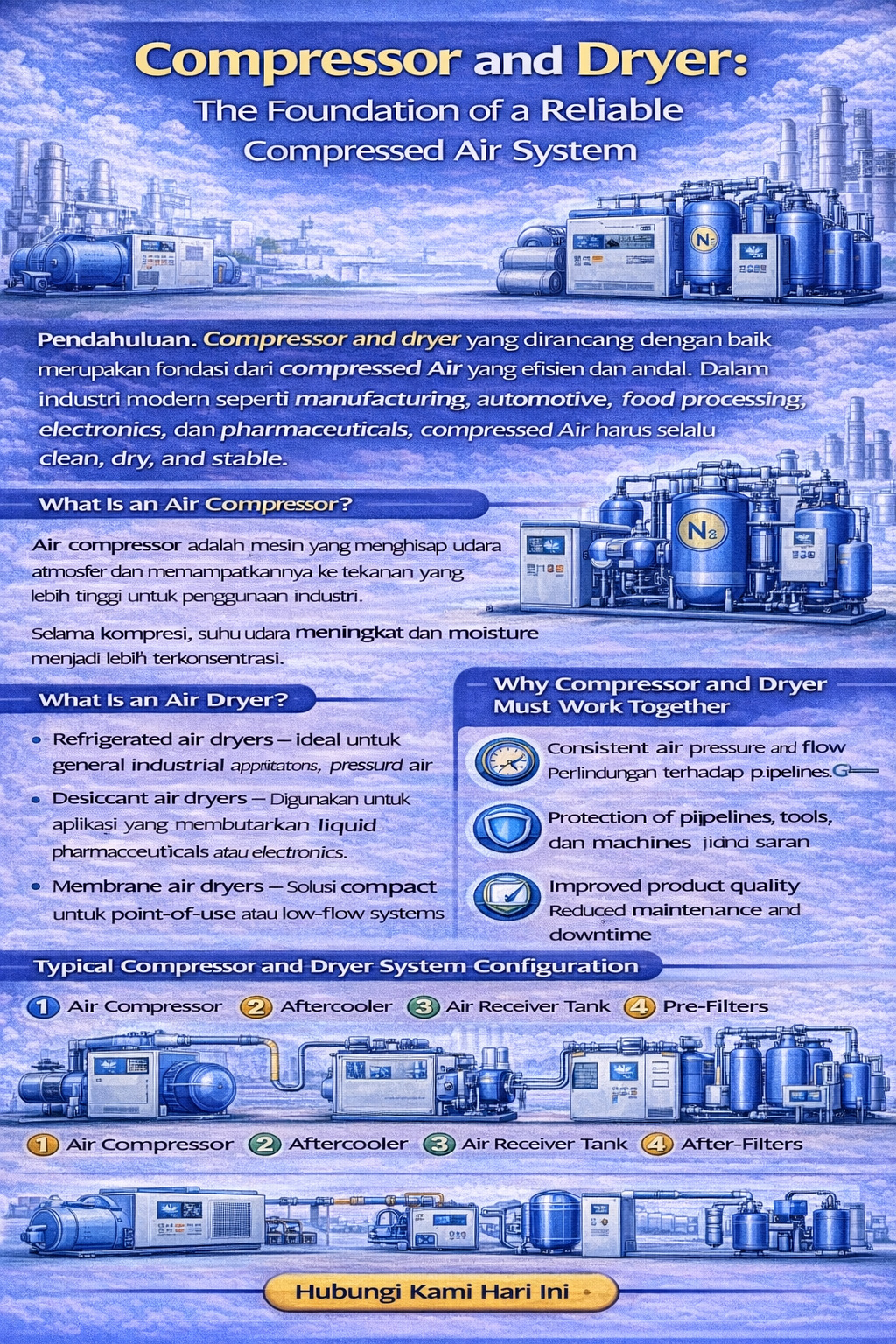

ToggleWhy a Refrigerated Compressed Air Dryer Is Essential

Moisture in compressed air systems can damage tools, corrode pipelines, and compromise product quality—leading to downtime and costly repairs.

A refrigerated compressed air dryer removes water vapor by cooling the air to near-freezing temperatures, causing condensation that is then drained. The result is clean, dry air that protects your equipment, prevents rust, and ensures operational efficiency.

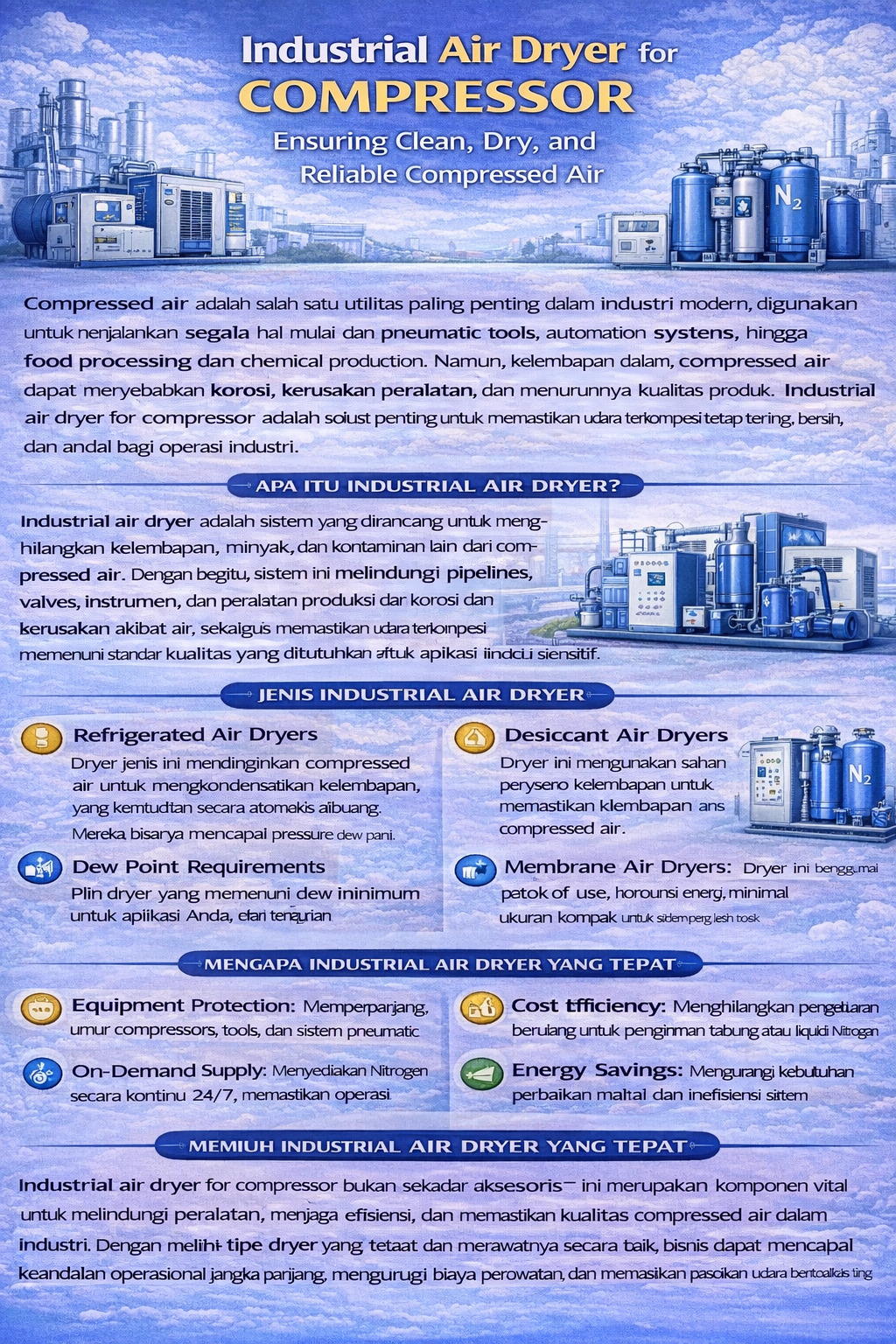

What Is a Refrigerated Compressed Air Dryer?

A refrigerated compressed air dryer reduces the moisture content of compressed air using a refrigeration-based cooling system.

As air passes through the dryer:

It is cooled to 35°F–50°F (1.6°C–10°C)

Water vapor condenses and is drained

Dry air is reheated slightly before returning to the system

Types of Refrigerated Air Dryers:

Non-Cycling Models: Run continuously; simple, reliable, and cost-effective for steady loads.

Cycling Models: Adjust cooling based on demand, saving energy during low usage periods.

How It Works

Hot, moist compressed air enters the dryer.

Air is cooled in a refrigeration heat exchanger.

Condensed water is collected and removed.

Dry, slightly reheated air exits for use in tools and machinery.

This process delivers consistent dew points and moisture-free air.

Key Features and Benefits

✅ Moisture-Free Compressed Air – Prevents rust, scaling, and equipment malfunctions.

✅ Energy-Efficient Operation – Cycling models reduce energy consumption during low demand.

✅ Easy Installation & Maintenance – Compact, plug-and-play design with minimal upkeep.

✅ Consistent Dew Point Control – Maintains approximately +3°C (37°F) for reliable performance.

✅ Extended Equipment Life – Protects valves, actuators, piping, and pneumatic tools.

Technical Specifications (Example)

| Parameter | Value |

|---|---|

| Flow Rate | 20 – 2000+ SCFM (customizable) |

| Dew Point | 35°F – 50°F |

| Power Supply | 110V / 220V / 380V options |

| Max Inlet Temperature | 120°F (standard models) |

| Max Operating Pressure | 150 PSI (10 bar) |

| Refrigerant Type | R134a / R407C |

| Drain Type | Automatic electronic |

| Control Panel | LED or digital with alarms |

Applications

Refrigerated compressed air dryers are ideal for:

🏭 Manufacturing Plants – Machine tools, automation, injection molding

🛠 Automotive Workshops – Spray painting, pneumatic tools, tire inflation

🥫 Food & Beverage – Packaging, bottling lines, conveyors

💊 Pharmaceutical Facilities – Cleanrooms, capsule filling

📦 Packaging Industry – Air knives, vacuum sealing, labeling

🏗 Construction – Pneumatic drills, sandblasting, jackhammers

Suitable for both small shops and large industrial lines, these dryers ensure a reliable, moisture-free air supply.

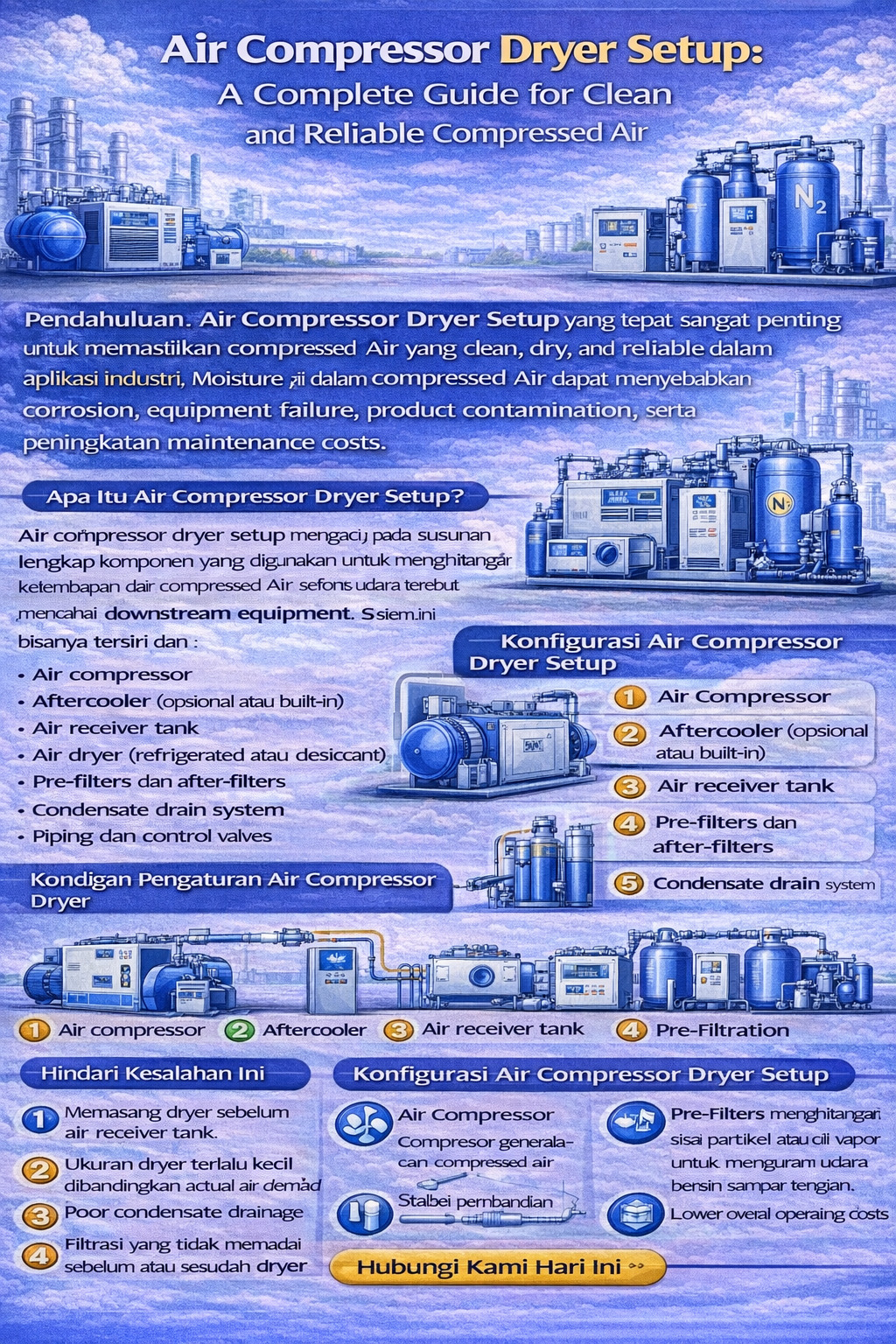

How to Choose the Right Dryer

Calculate Flow Requirements – Match compressor output in SCFM or m³/min.

Check Inlet Conditions – Evaluate temperature and humidity.

Consider Energy Efficiency – Cycling models save power long-term.

Plan Maintenance Access – Ensure room for drains and filter changes.

Balance Budget & Performance – Optimize initial investment versus long-term savings.

Maintenance Tips

Clean condenser coils monthly

Test automatic drain valves weekly

Replace pre-filters regularly

Verify dew point readings

Schedule annual refrigerant inspections

Routine maintenance ensures energy efficiency, reliable performance, and a long service life.

Frequently Asked Questions

Q1: How does it work?

It cools air to 35°F–50°F, condensing moisture for removal, delivering dry air to your system.

Q2: Difference between cycling and non-cycling dryers?

Cycling dryers adjust cooling based on demand to save energy; non-cycling dryers run continuously.

Q3: Typical dew point?

+3°C (37°F), suitable for most industrial applications.

Q4: Can it be installed outdoors?

Standard models are indoor rated; weatherproof versions are available.

Q5: Is pre-filtration necessary?

Yes. Pre-filters remove oil and particles, extending dryer life.

Conclusion: Invest in Reliable Air Quality

A refrigerated compressed air dryer is essential for protecting machinery, ensuring product quality, and reducing maintenance costs.

Choose a dryer designed to perform under pressure, delivering energy-efficient, reliable, and consistent dry air for your compressed air system.

📞 Contact us today for a quote or expert sizing assistance.