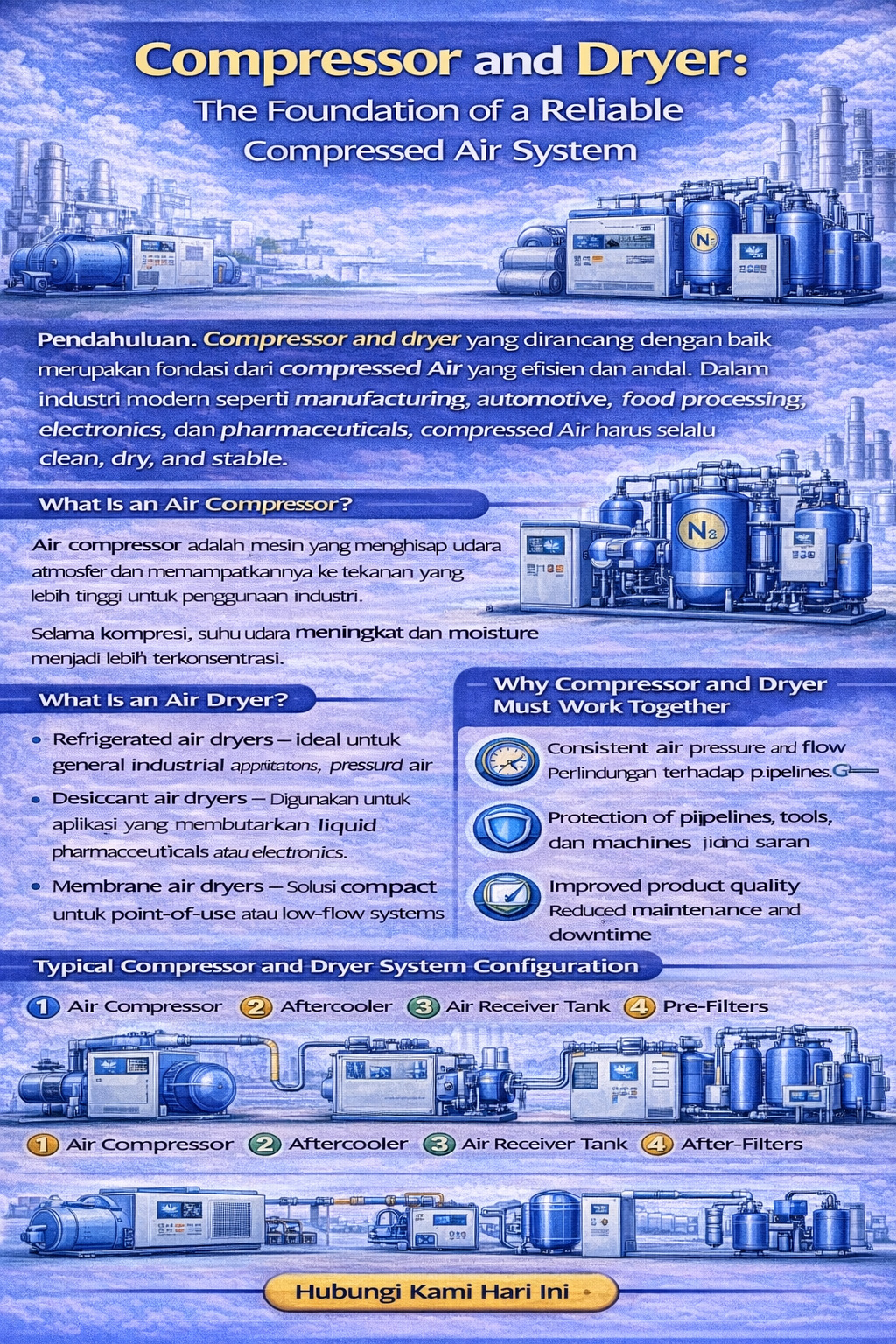

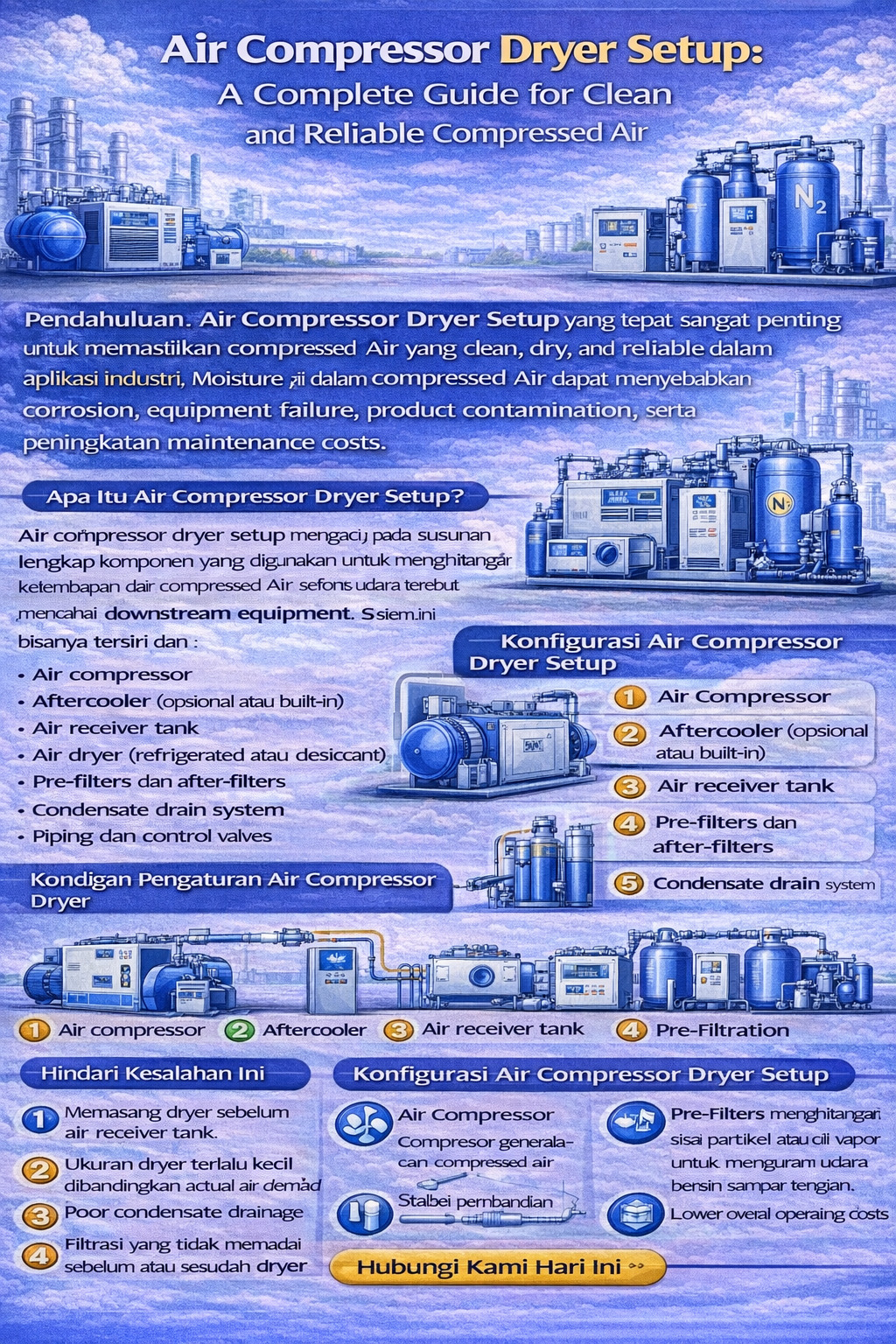

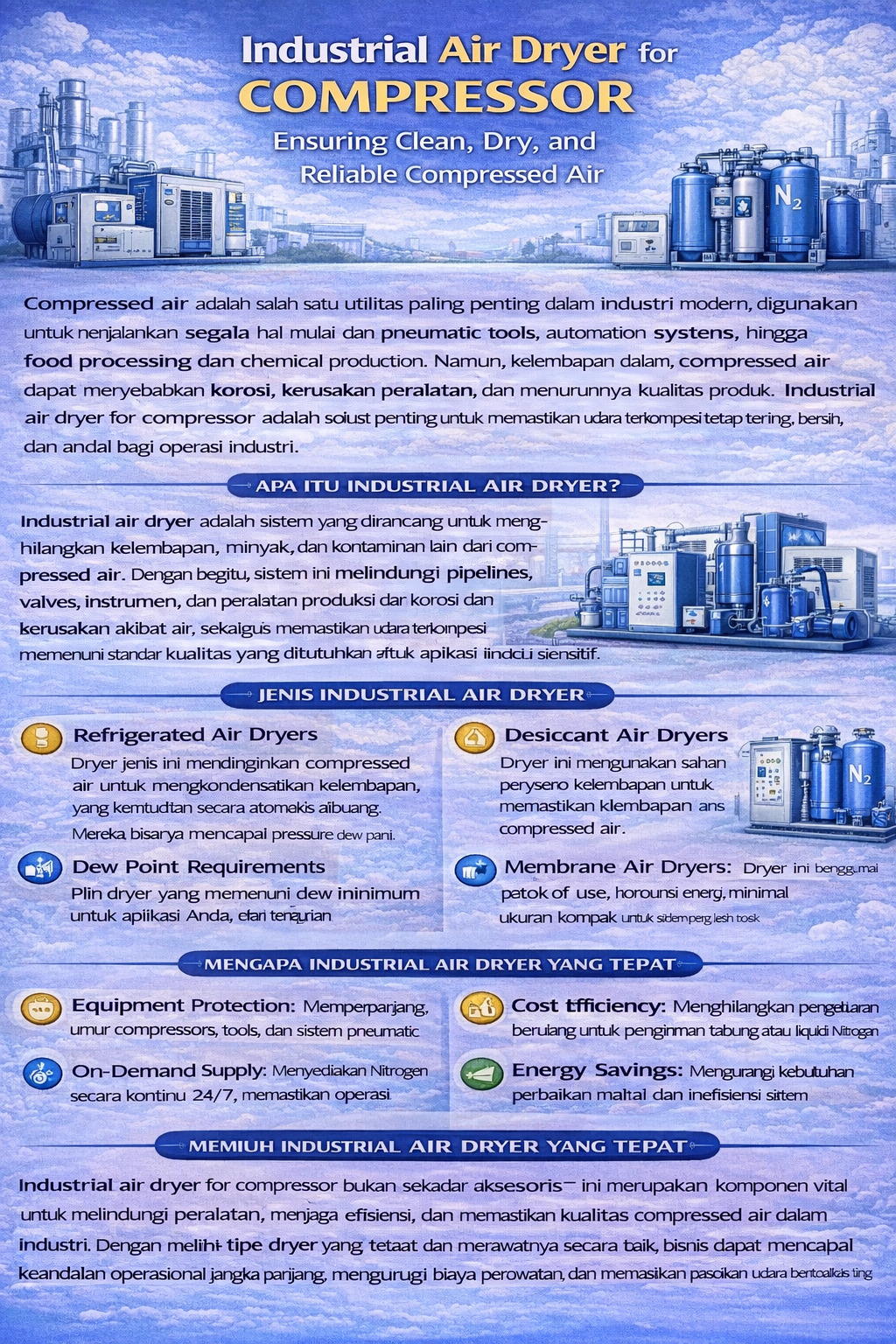

Desiccant air dryers for compressed air are essential for industrial systems that demand ultra-dry, moisture-free air. Unlike refrigerated dryers, these dryers use adsorption technology to remove water vapor, delivering a consistent pressure dew point as low as -40°C or even -70°C.

Ideal for pharmaceuticals, electronics, food processing, and precision manufacturing, our desiccant air dryers ensure unmatched reliability, energy efficiency, and continuous operation.

Table of Contents

ToggleKey Features

✅ Ultra-Low Dew Point – Protects equipment from corrosion, freezing, and moisture-related failures.

✅ Dual Tower Design – Alternating adsorption and regeneration towers ensure uninterrupted drying.

✅ Energy-Saving Control – Dew point controllers and purge-saving technology reduce compressed air loss.

✅ Robust Construction – Industrial-grade steel vessels with corrosion-resistant inner linings; CE/ASME certified.

✅ Simple Maintenance – Easy access to desiccant beds, valves, and filters minimizes downtime.

✅ Modular Configuration – Scalable for 5 CFM to 10,000+ CFM air flow capacities.

Our desiccant air dryers are engineered to deliver stable, dry air even in extreme industrial conditions.

Operating Conditions & Technical Requirements

| Parameter | Specification |

|---|---|

| Inlet Air Pressure | 4 – 10 bar (58 – 145 psi) |

| Inlet Air Temperature | ≤ 45°C (113°F) |

| Ambient Temperature | 5 – 50°C (41 – 122°F) |

| Max Dew Point | Down to -70°C (-94°F) |

| Regeneration Method | Heatless / Heated / Blower Purge (optional) |

| Power Supply | 220V/1Ph/50Hz or 380V/3Ph/50Hz (customizable) |

Technical Specifications (Example: 100 CFM Unit)

| Model | DAD-100 |

|---|---|

| Air Capacity | 100 CFM |

| Dew Point | -40°C (Standard) / -70°C (Optional) |

| Pressure Range | 4 – 10 bar |

| Desiccant Type | Activated Alumina / Molecular Sieve |

| Regeneration Type | Heatless / Heated (Optional) |

| Power Consumption | 60W – 1.5kW (model-dependent) |

| Inlet/Outlet Size | 1” BSP / NPT |

| Dimensions (L×W×H) | 900 × 600 × 1200 mm |

| Weight | 180 kg |

Full range available to meet various system capacities and moisture control requirements.

Application Scenarios

Desiccant air dryers for compressed air are essential wherever dry air is critical:

🧪 Pharmaceutical & Biotech – Clean-room and packaging integrity

💻 Electronics & Semiconductors – Prevents short circuits from moisture

🧼 Food & Beverage – Meets hygiene standards in production and packaging

🛢️ Oil & Gas / Petrochemicals – Protects instruments, pipelines, and pneumatic controls

🏭 Automotive & Aerospace – Ensures surface quality in painting and assembly lines

🧯 Fire Protection Systems – Prevents corrosion in dry-pipe sprinkler systems

❄️ Cold Climate Installations – Prevents freeze-ups in outdoor compressed air lines

FAQ – Desiccant Air Dryers

Q1: What are desiccant air dryers used for?

A: They remove moisture from compressed air in critical applications to prevent corrosion, freezing, or process contamination.

Q2: Difference between refrigerated and desiccant dryers?

A: Refrigerated dryers condense moisture by cooling air; desiccant dryers use adsorption to achieve much lower dew points.

Q3: Typical dew point achieved?

A: Standard -40°C, optional -70°C for ultra-dry applications.

Q4: How often should the desiccant be replaced?

A: Typically every 1–3 years, depending on usage and environment.

Q5: Are custom solutions available?

A: Yes. OEM/ODM services include custom capacity, layout, power options, and regeneration methods.

Why Choose Our Desiccant Air Dryers?

🌐 Global Standards – CE/ASME certified and globally accepted

⚙️ Customization – Wide range of sizes and options

📦 Fast Delivery – In-stock models and fast production for custom orders

🧠 Smart Controls – Optional dew point sensors and purge control systems

🔧 Reliable Support – Lifetime technical assistance and spare parts

Get a Quote Today

Ensure your operations run smoothly with high-performance desiccant air dryers for compressed air.

📞 Contact us now for a quote, technical consultation, or a free application analysis.