Table of Contents

ToggleWhy Moisture Is Your Worst Enemy in Compressed Air Systems

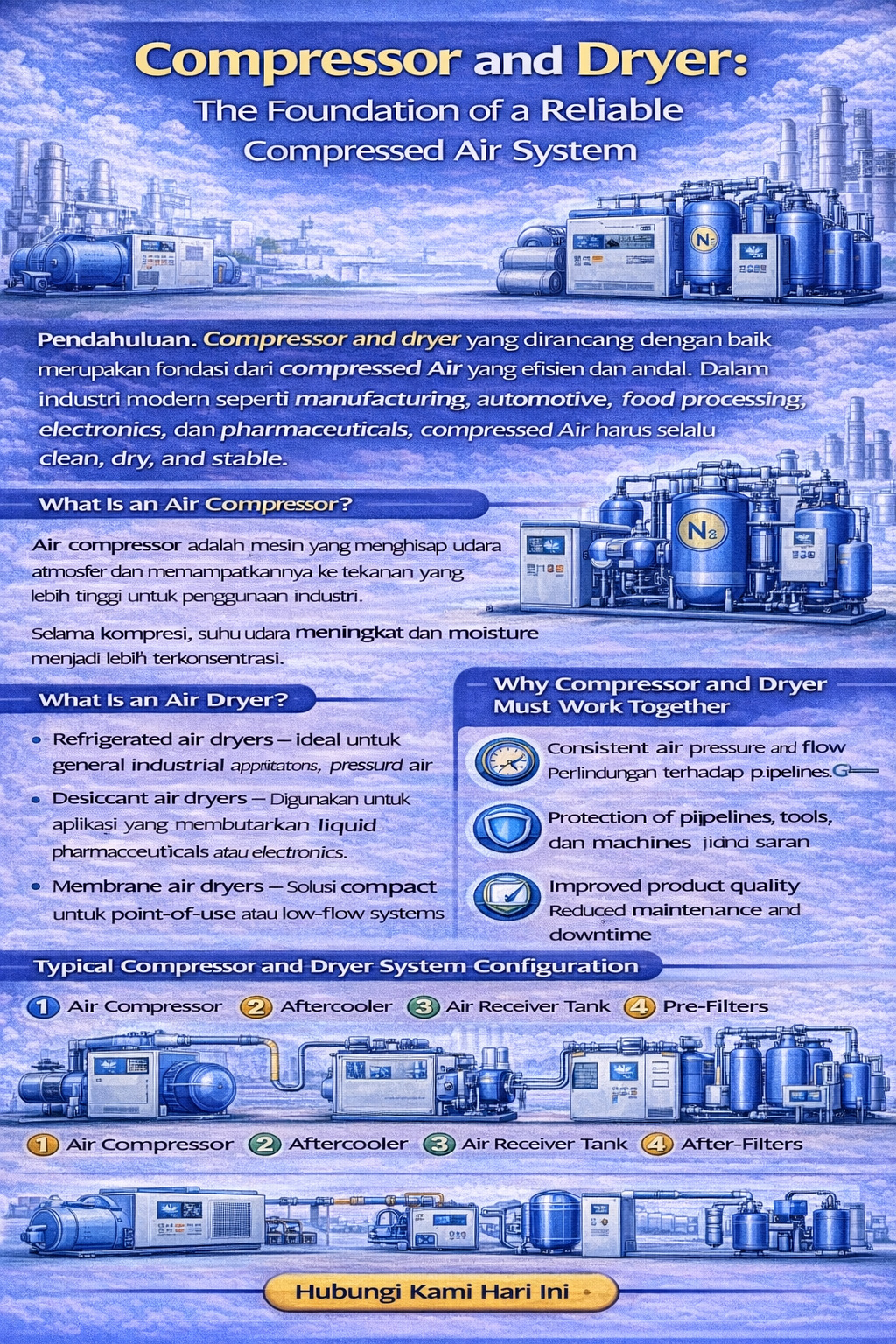

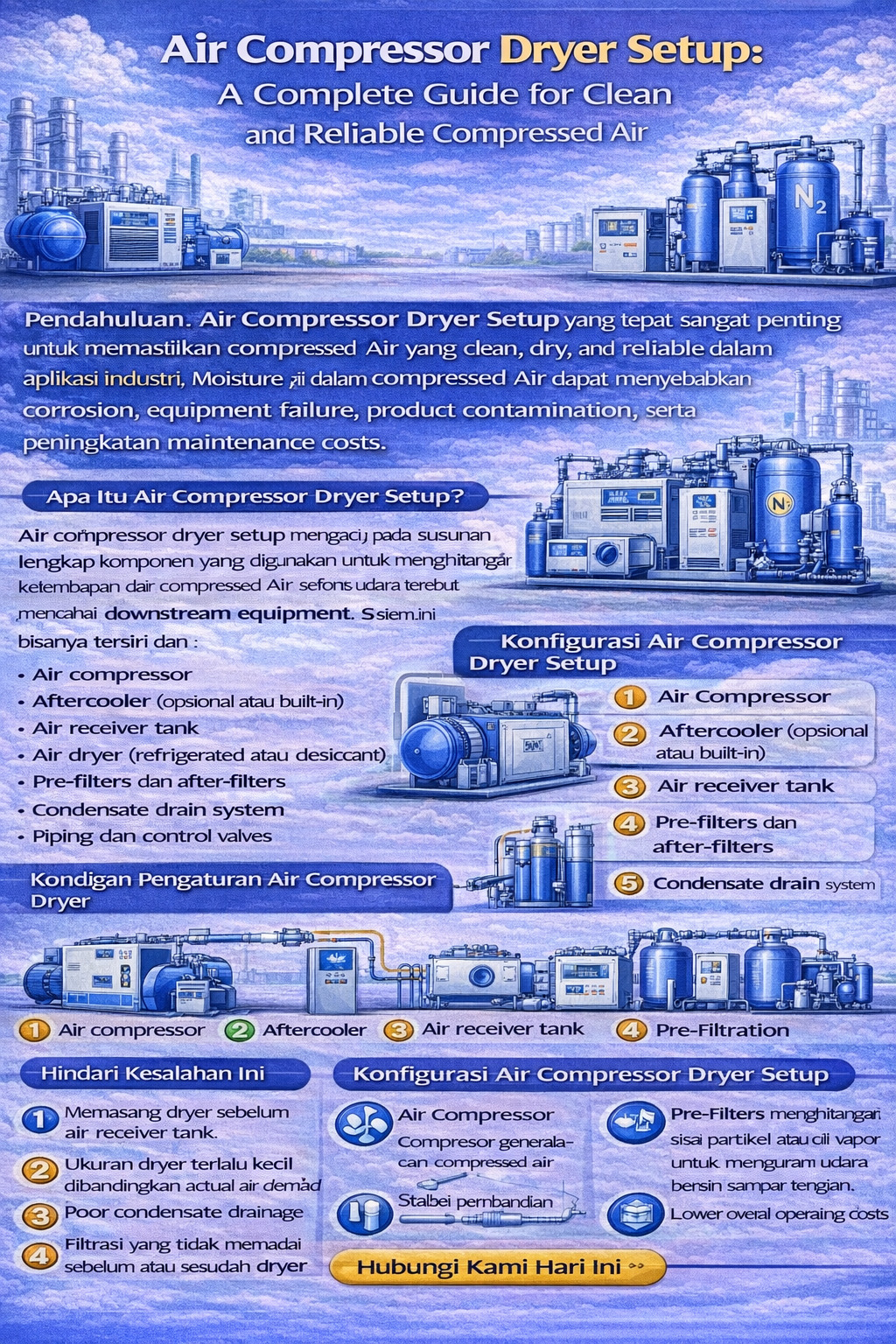

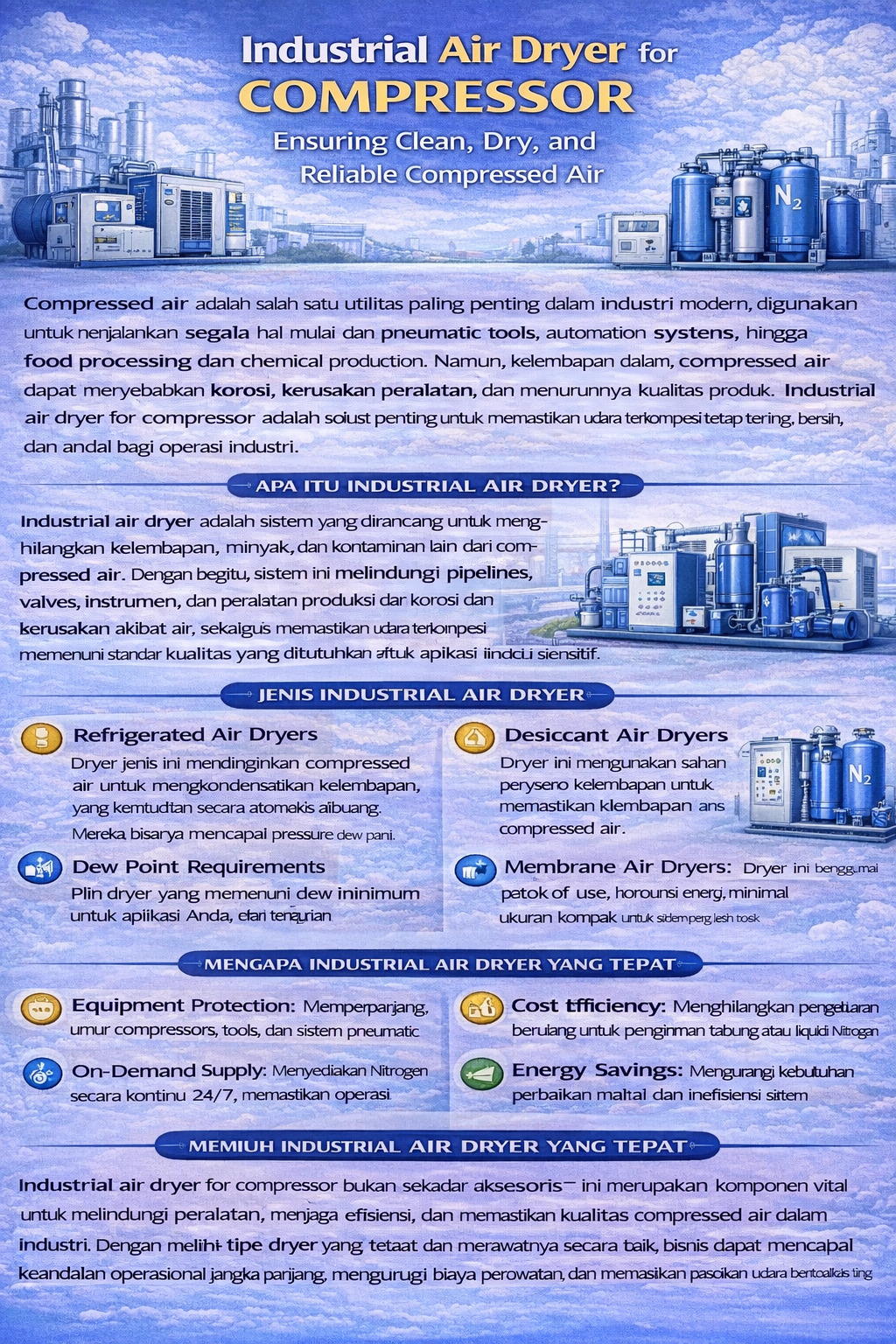

Compressed air is vital to industries such as manufacturing, food processing, automotive, and pharmaceuticals.

However, there’s one common and costly problem—moisture.

Water vapor in compressed air can cause:

⚠️ Pipe corrosion

⚠️ Rusted pneumatic tools

⚠️ Malfunctioning valves and cylinders

⚠️ Contaminated or defective products

⚠️ Costly maintenance and downtime

That’s where the air compressor desiccant dryer becomes essential. Unlike refrigerated dryers, desiccant dryers deliver ultra-low dew points, often reaching -40°F (-40°C) or even -100°F (-73°C). This makes them the perfect choice for sensitive applications or cold-climate environments.

What Is an Air Compressor Desiccant Dryer?

An air compressor desiccant dryer is a moisture removal system that uses adsorption technology to eliminate water vapor from compressed air.

Instead of cooling air to condense moisture, it passes air through a desiccant material—typically activated alumina or molecular sieve—which adsorbs (captures) the moisture molecules.

How It Works

Compressed air enters the desiccant chamber.

Moisture is adsorbed by the desiccant media.

Dry air exits with a dew point as low as -40°F to -100°F.

A second tower regenerates the saturated desiccant for reuse.

This twin-tower design allows continuous operation—while one tower dries the air, the other regenerates.

Types of Air Compressor Desiccant Dryers

✅ Heatless Desiccant Dryers

Use a portion of the dried compressed air to purge moisture from the desiccant.

✔️ Cost-effective

✔️ No external heating required

✅ Heated Desiccant Dryers

Use electric heaters for regeneration, minimizing purge air loss.

✔️ Ideal for high-volume operations

✔️ Greater energy efficiency

✅ Blower Purge Desiccant Dryers

Use ambient air via a blower and heater for regeneration.

✔️ Zero compressed air loss

✔️ Best for large-scale, energy-conscious facilities

Why Choose an Air Compressor Desiccant Dryer?

🌡 Ultra-Low Dew Points: Perfect for precision processes in pharmaceuticals, electronics, and coating lines.

⚙️ Extended Equipment Life: Prevents corrosion and component wear.

❄️ Cold Climate Compatibility: Operates efficiently where refrigerated dryers cannot.

🏭 Heavy-Duty Design: Built for continuous, high-capacity use.

Key Features of Our Air Compressor Desiccant Dryer

| Feature | Description |

|---|---|

| Flow Capacity | 20 – 5000+ CFM (customizable) |

| Pressure Dew Point | -40°F to -100°F |

| Inlet Pressure Range | 4 – 10 bar |

| Inlet Air Temperature | Up to 120°F (optional up to 150°F) |

| Desiccant Media | Activated Alumina / Molecular Sieve |

| Control System | PLC with LCD Display and Alarm Monitoring |

| Regeneration Type | Heatless / Heated / Blower Purge |

| Certifications | CE / ISO9001 / UL (upon request) |

Performance Advantages

🔧 Maximize Performance — Minimize Downtime

Our air compressor desiccant dryers provide:

✅ High-capacity moisture removal

✅ Modular design for quick servicing

✅ Energy-efficient regeneration cycles

✅ Built-in dew point monitoring

✅ Rugged steel frames and corrosion-resistant internals

💬 Whether you’re operating a food-grade facility or a precision electronics line, our dryers ensure dependable performance—even under demanding conditions.

Typical Applications

🏭 Pharmaceutical Manufacturing – Capsule drying, cleanroom air

🛠 Automotive Paint Shops – Flawless surface coating

🔬 Laboratories & R&D Facilities – Precise air quality control

🧊 Food Processing – Hygienic and moisture-free packaging

⚙️ Industrial Automation – Protects sensors and actuators

🏗 Construction & Outdoor Operations – Prevents freeze-ups in cold weather

Maintenance Tips

To ensure long-term efficiency and consistent dew point control:

🔧 Replace desiccant every 12–24 months (based on usage)

🔧 Check and replace filter elements regularly

🔧 Inspect valves, drains, and pressure gauges

🔧 Calibrate dew point meters semi-annually

🔧 Record cycle counts and regeneration data

Frequently Asked Questions (FAQ)

Q1: What dew point does an air compressor desiccant dryer provide?

A: Standard models achieve -40°F, with options for -100°F for critical operations.

Q2: How long does the desiccant last?

A: Typically 1–2 years, depending on air quality and duty cycle.

Q3: Is a pre-filter necessary?

A: Yes. A coalescing pre-filter removes oil and particulates before the dryer, protecting the desiccant.

Q4: How does it compare to a refrigerated dryer?

A: Desiccant dryers deliver lower dew points and are suited for cold or moisture-sensitive environments.

Q5: Can it be installed outdoors?

A: Standard models are for indoor use; weatherproof enclosures are available upon request.

Conclusion: Go Beyond “Dry Enough” — Go Ultra-Dry

When precision, reliability, and efficiency matter, choose a high-performance air compressor desiccant dryer.

Our systems deliver ultra-dry air, energy-efficient regeneration, and long-lasting durability to keep your operations running smoothly.

📌 Need help choosing the right dryer?

Our engineers can assist with sizing, flow rate, regeneration type, and dew point configuration to match your exact application.

💬 Contact us today to request a quote or free consultation.